Passivated Emitter Rear Cell (PERC) technology is a technology that adds an additional layer on the back of the solar cell, reflecting part of the photons that manage to pass through the cell, increasing the overall efficiency.

Since PERC (Passivated Emitter Rear Cell) monocrystalline rear passivation technology has almost reached its maximum conversion rate (around 23.5%), there are other technologies with a more promising future.

Intrinsic thin-film heterojunction technology (hereafter HJT), which has achieved an efficiency of about 22.5%, may win the competition with its predecessors and become the leading technology in the next generation of PV cells.

Even so, HJT technology must overcome some difficulties that may jeopardize its mass commercialization. Among these obstacles are the high cost of N-type silicon wafers, the high consumption of silver paste, as well as the loss of module encapsulation.

In order to eliminate these problems, some companies propose combining HJT technology with other technologies to get the most out of each of them.

MWT technology can solve many HJT-related difficulties and greatly improve the commercialization of HJT cells. The integration of MWT and HJT technologies can drive the mass production of high-efficiency MWT+HJT solar cells, thereby not only improving the conversion efficiency of the cells but also helping to reduce the cost per watt.

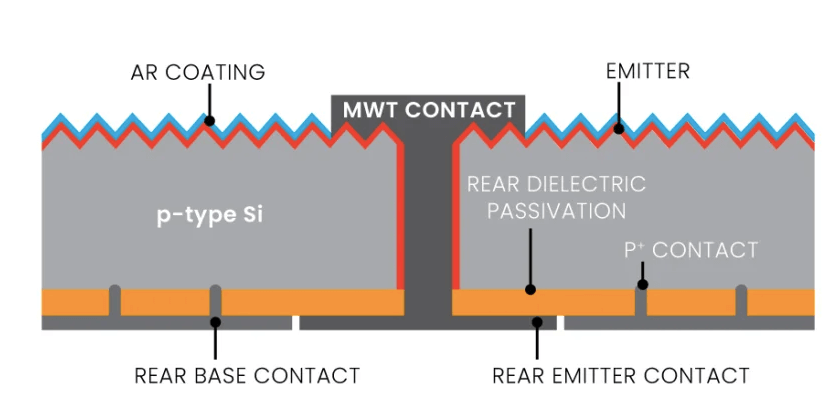

The semi-flexible module is based on Metal Wrap Through Technology (MWT). MWT is an advanced back contact technology that allows increasing the efficiency of the solar cell and the module by 3% over conventional modules.

It is achieved by eliminating the front bus bar and deploying the positive and negative electrodes at the rear.

Recently, high-efficiency N-type monocrystalline solar cells have been developed that combine MWT and HJT technology and are capable of achieving an efficiency of 25%.

The combination of the two technologies maintains a strong competitive edge by:

- They achieve a 2.5% higher conversion rate than PERC technology;

- 0.5 to 1% higher conversion than HJT technology;

- Thinner wafer thickness, about 20% thinner than conventional cells, thus decreasing silicon usage;

- 20% less silver paste is used;

- The unit cost of the solar cell is reduced by up to 10% per W.

As mentioned above, another problem with the production of the HJT module is the encapsulation process. In this process, it is necessary to avoid soldering with conventional high-temperature techniques by using silver paste at low temperatures.

HANERGY's semi-flexible solar modules have an advanced 2-D encapsulation scheme of a conductive base plate together with a conductive adhesive, a technology already implemented in its MWT module that completely eliminates the application of soldering (bus bars).

As we have seen, the combined use of HJT and MWT technologies makes it possible to apply the technical advantages of each of them in order to overcome the main drawbacks or difficulties that HJT technology may have in its commercialization.

Not only that, but it also improves conversion efficiency and reduces manufacturing costs. In short, the result combining MWT and HJT technologies results in high efficiency and low cost, making them both good partners.

Interested in installing new solar technologies or distributing them? Join the international network of Solar Architecture and Smart Cities, BIPV GLOBAL, free of charge. https://bipvglobal.com/contact

We also invite you to share this news on your social networks: